e-stress

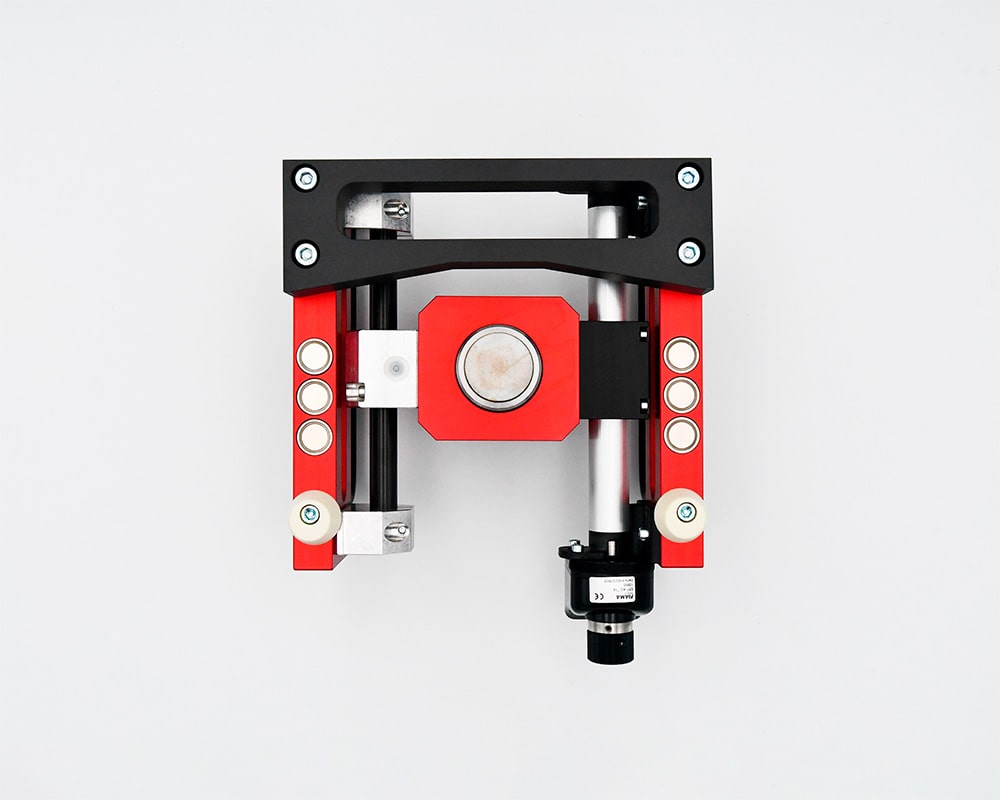

Residual stresses measurement system for railway wheels

Including acquisition hardware, visualization software and EMAT technology, this device is designed for manufacturing and maintenance operations. Compatible with standard wheel manufacturing steels (ER6, ER7, ER8, ER9) and inspection requirements in compliance with EN 13262 – Annex D.

If you are interested, please contact our technical department.

Features

Integrated electro magnetic acoustic (EMAT) technology.

Capable of penetrating surface coating and corrosion.

No beam steering errors caused by misalignment of the transducer with surface.

Correct contact between sensor and wheel

Portable design.

Easy maintenance.