e-blade

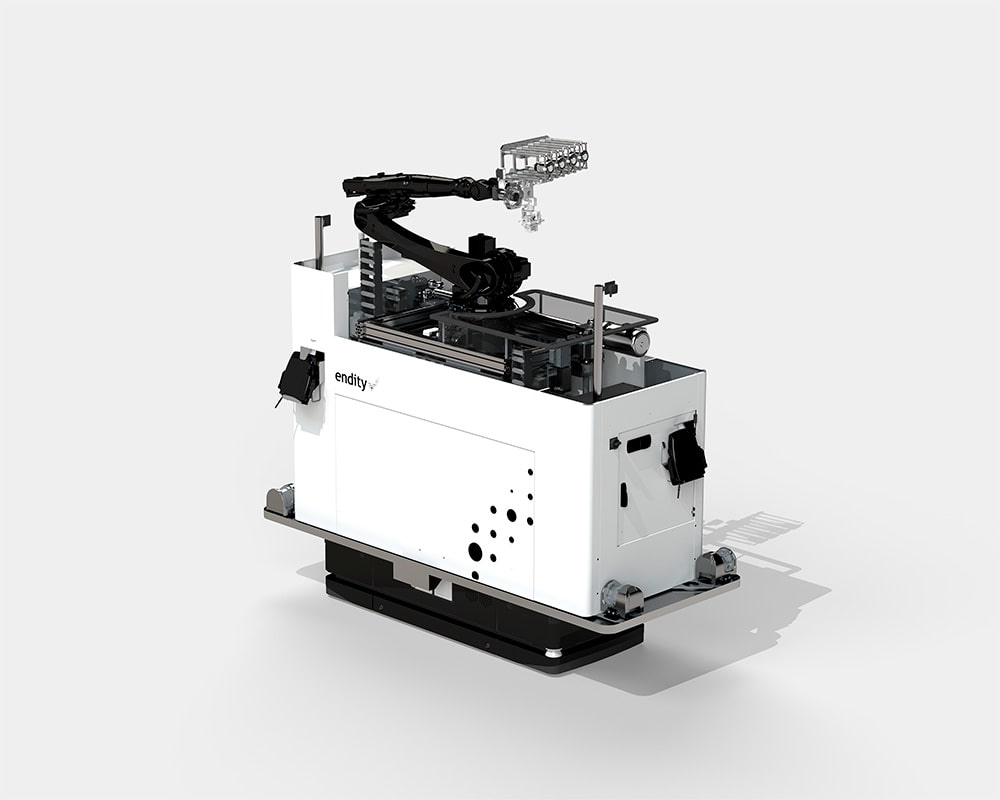

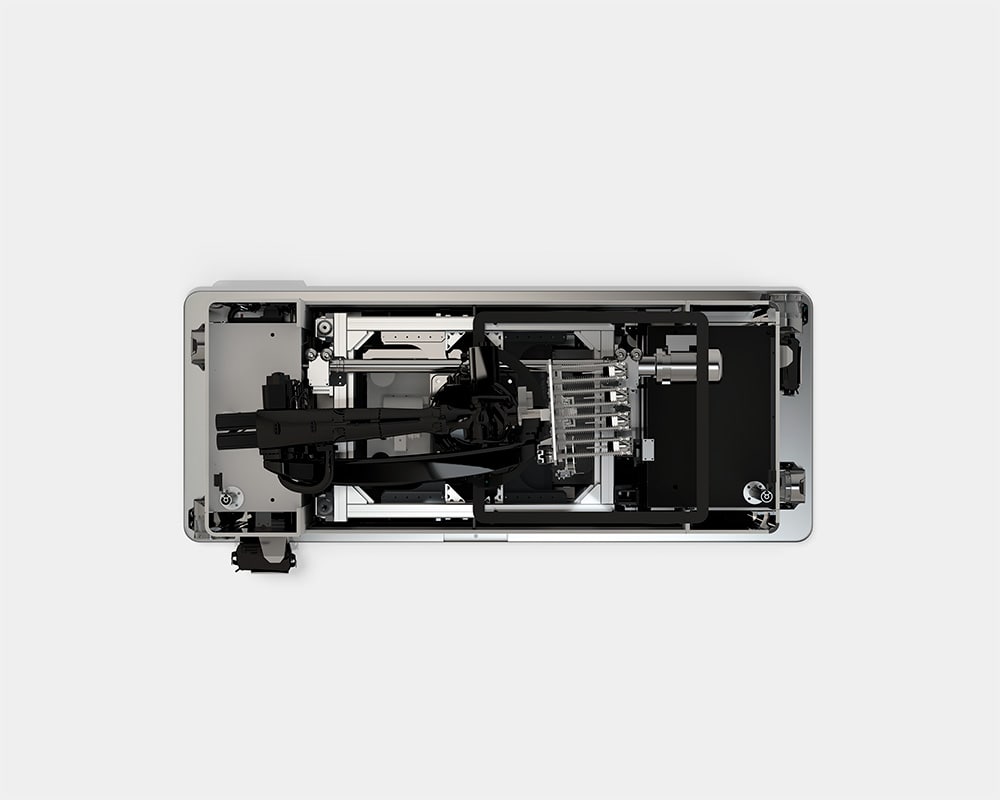

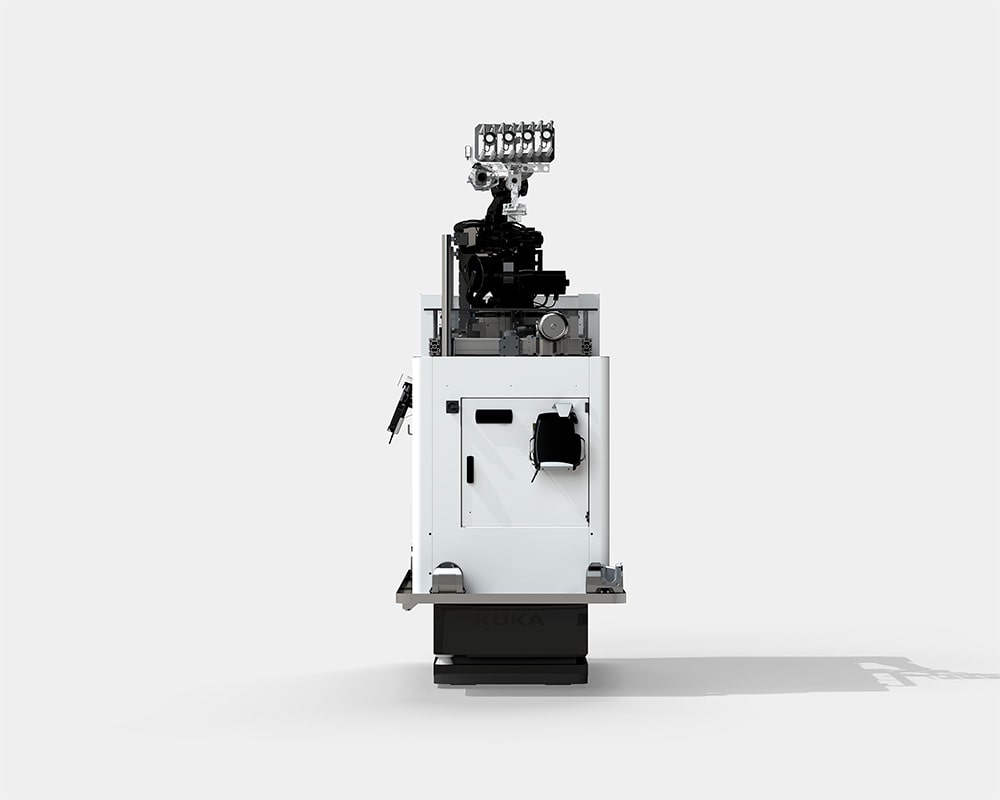

Autonomous ultrasonic wind blade inspection system

Autonomous inspection system for a wide range of applications such as material integrity or verification of adhesive joints like CAP WEB, REAR WEB or TRAILING EDGE. Possibility of applying conventional or array technology with an inspection velocity up to 500mm/s.

If you are interested, please contact our technical department.

Features

Vision module to monitor the inspected area.

AI-based data evaluation process.

Inspection repeatability and reliability.

Adaptable probe head to integrate conventional (UT) or arrays (PAUT) transducers.

Auto-calibration functions.

Workpiece tracking.

+8 hours autonomy.